Powder Coating vs. Stone Coating

Metal roofing, which is quickly gaining popularity in the U.S., is now offered in many different materials, styles, colors, and finishes. With metal roofing products now manufactured to mimic the appearance of traditional styles such as wood shake, clay tile, and asphalt shingles, customers have more options than ever before. However, when deciding what metal roof offers the best long term solution for durability and appearance, building owners need to consider the quality of the finish on the metal panels. The two main surface finishes in the industry today are powder coating and stone coating. However, they are distinctly different, with powder coating being, by far, the superior product in long-term protection and resistance to color fading.

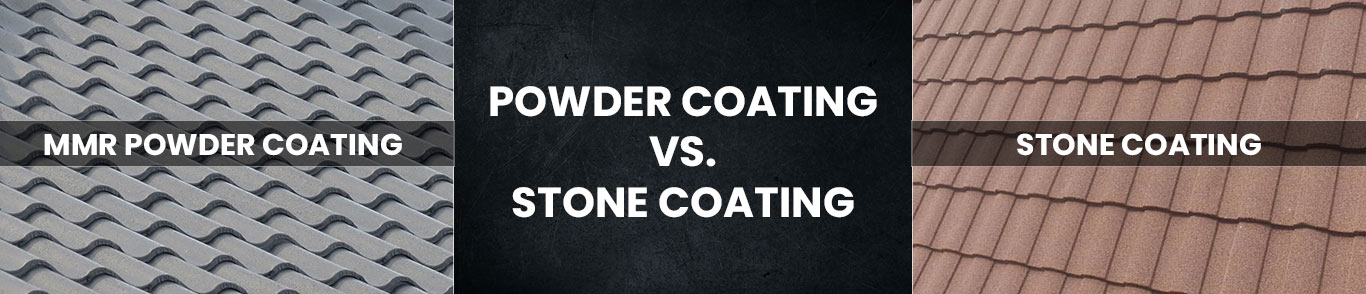

The Difference Between Powder and Stone Coating

While both finishes are designed to provide a protective surfacing for the underlying metal, they are quite different in composition and application. The metal base for both surfacing’s are typically made of galvanized steel or aluminum.

Powder Coating

The powder coating process involves electrostatically applying a specialized powder to the metal surface, which is cured under heat, forming a hard, protective layer. Powder coating is highly resistant to chips, cracks, peeling, chemical exposure, and typically has a smooth and even finish. The electrostatically charged powder adheres evenly to the metal surface, reducing the risks of run, drips, or uneven coating. MMR applies our patented powder coating to premium steel, with a Kynar protected paint finish already installed, for maximum panel protection.

Stone Coating

In the stone coating process, a layer of adhesive is applied to an unpainted metal surface, followed by ceramic-coated stone chips. These chips are typically made from natural minerals, such as basalt or granite, and are available in various colors to produce different looks. The stone coating acts as a barrier against UV rays, helps prevent fading, and protects the underlying metal. However, since the stone chips contain the color for the panel, once lost, color fading is evident.

Why Powder Coating Protects Better Than Stone Coating

Simply put, powder coating provides superior protection on metal roofing panels due to its method of application and ability to permanently bond with the metal surfacing. Stone coating relies on an adhesive to hold the ceramic chips in place, which is problematic for several reasons. Inconsistencies in the adhesive application, poor preparation of the panel during coating, and varying levels of thickness of the chips can all result in panel delamination and chip loss, as shown in the photos below.

The photo to the right shows a powder coated metal panel that was impacted by a large tree fall after a local tornado. While significant damage to the metal panel occurred, due to the sheer weight of the tree, the powder coating granules were not dislodged or affected. This enhanced durability and longevity of powder coating versus stone coating is a significant advantage to the long-term performance of the

The photo to the right shows a powder coated metal panel that was impacted by a large tree fall after a local tornado. While significant damage to the metal panel occurred, due to the sheer weight of the tree, the powder coating granules were not dislodged or affected. This enhanced durability and longevity of powder coating versus stone coating is a significant advantage to the long-term performance of the